Ama-pilducts

Sinikezela ngezixazululo ezahlukahlukene zezidingo zakho, noma ngabe udinga izinto ezijwayelekile noma umklamo okhethekile.Inyuphu ye-pneumatic

Incazelo Esikhathi Eside

Izici ezibalulekile ze-Air hoists:

Amandla omoya acindezelwe: I-pneumatic hoist inikwa amandla ngumoya ocindezelwe, okuwumthombo wamandla ohlanzekile futhi omningi. Le ndlela yamandla ihlinzeka ngokusebenza okungaguquki futhi okuthembekile, okwenza ama-air akopiya enza imisebenzi ephakeme yokuphakamisa.

Ukulawulwa Okuqondile: Ama-Air Hoist anikela ngokuqondile ukulawulwa kwemithwalo, okuvumela abahlinzeki ukuthi baphakamise, baphansi, kanye nemithwalo emincane ngokunemba. Lokhu kunemba kubalulekile, ikakhulukazi ezimbonini lapho ukuphepha nokuphatha okubucayi kubaluleke kakhulu.

Ijubane eliguqukayo Lesi sici sithuthukisa ukuguquguquka nokusebenza kahle.

Ukuqina: I-pneumatic hoist idume ngokwakhiwa okuqinile nokumelana nokuqina kwezimo ezinzima zokusebenza. Imvamisa isetshenziswa ezindaweni ezifunwayo njengamathoyizi, ama-Whiftyards, kanye namasayithi okwakha.

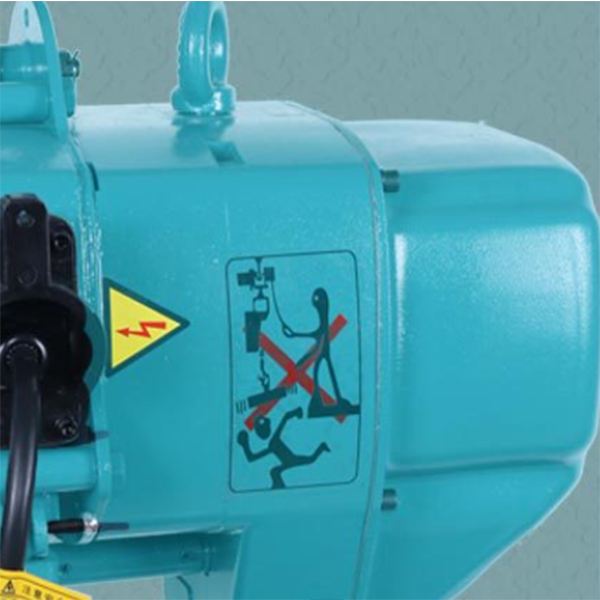

Ukuvikelwa okugcwele ngokweqile: I-Pneumatic Hoost yanamuhla ifakwe izici zokuphepha njengokuvikela ngokweqile ukuvikela izingozi ezibangelwa imithwalo ngokweqile. Lezi zindlela zokuphepha zithuthukisa ukuphepha emsebenzini.

I-Compact Design: I-Pneumatic Hoost ivame ukuba nedizayini ehlangene futhi engasindi, ibenze kube lula ukufaka futhi inikeze izikhala eziqinile. Lokhu kuguquguquka kwamanani avumelanayo kunhlobonhlobo yezicelo.

Imininingwane ukuboniswa

Umniningwane

I-Shell ebonakalayo yokuvikelwa:

Ukulungiswa okusheshayo kwesikhundla seTheChain ngokulungiswa okusheshayo kwedivaysi yokuvikela umthwalo we-wawwwheelSton

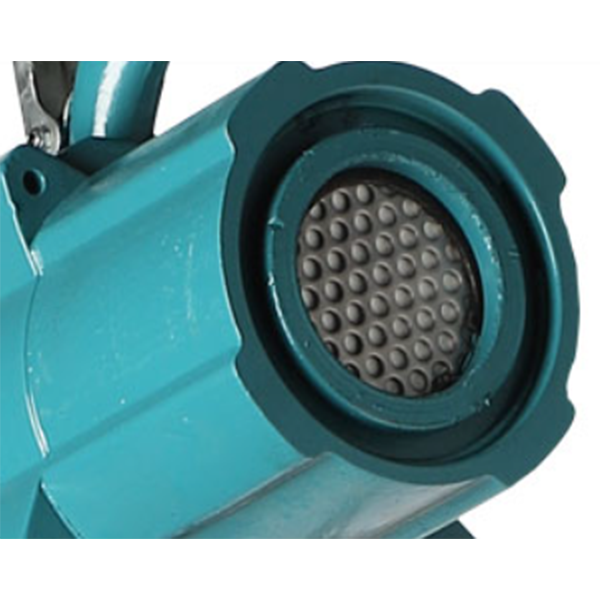

I-2.cast gear:

Eyenziwe ngensimbi ye-alloy ngu-carb-urwingquentquenting Noise Wezerchermow kanye nokusebenza kahle;

3.G80 Ibanga le-Manganese Steel Scar:

Akuwona amandla amahle kakonakalisa namandla amakhulu, ukuphepha okwengeziwe;

I-ONEL ye-MAN MANGANESE:

Eyenziwe ngensimbi ye-alloy ngu-carb-urwingquentquenting Noise Wezerchermow kanye nokusebenza kahle;

| Isifanekiso | umuvo | 3Ti | 5Ti | I-6Ti | 8Ti | I-10Ti | ||||||

| ukucindezela | nqabela | 3.2 | 5 | 6.3 | 8 | 10 | ||||||

| Thuthukisa amandla | t | 4 | 6 | 4 | 6 | 4 | 6 | 4 | 6 | 4 | ||

| Inani lamaketanga |

| 1 | 2 | 2 | 2 | 2 | ||||||

| Amandla okukhipha ama-motor | kw | 1.8 | I-3.5 | 1.8 | I-3.5 | 1.8 | I-3.5 | 1.8 | I-3.5 | 1.8 | ||

| Isivinini sokuphakamisa umthwalo ophelele | m / min | 2,5 | 5 | 1.2 | 2,5 | 1.2 | 2,5 | 0.8 | 1.6 | 0.8 | ||

| Isivinini esiphezulu esingenalutho | m / min | 6 | 10 | 3 | 5 | 3 | 5 | 2 | 3.2 | 2 | ||

| Isivinini esigcwele sokulayisha umthwalo | m / min | 7.5 | 10.8 | 3.6 | 5.4 | 3.6 | 5.4 | 2,5 | 3.4 | 2,5 | ||

| Ukusetshenziswa kwegesi okugcwele - ngesikhathi sokuphakamisa | m / min | 2 | 4 | 2 | 4 | 2 | 4 | 2 | 4 | 2 | ||

| Ukusetshenziswa kwegesi okugcwele okugcwele - ngesikhathi sokuzalwa | m / min | I-3.5 | 5.5 | I-3.5 | 5.5 | I-3.5 | 5.5 | I-3.5 | 5.5 | I-3.5 | ||

| Ukuhlangana kwe-tracheal |

| G3 / 4 | ||||||||||

| Usayizi wepayipi | mm | 19 | ||||||||||

| Ukuphakamisa okujwayelekile nesisindo ngaphakathi kobubanzi obude | mm | 86 | 11 | 11 | I-156 | I-156 | ||||||

| Usayizi weketanga | mm | I-13X36 | I-13X36 | I-13X36 | 16x48 | 16x48 | ||||||

| Isisindo se-Chain ngemitha ngayinye | kg | 3.8 | 3.8 | 3.8 | 6 | 6 | ||||||

| Phakamisa ukuphakama | m | 3 | ||||||||||

| Ubude obujwayelekile bePipeline ubude | m | 2 | ||||||||||

| Umsindo ogcwele umthwalo nge-silencer - Ukwanda ngo-1 | ipibekh | 74 | 78 | 74 | 78 | 74 | 78 | 74 | 78 | 74 | ||

| Umsindo ogcwele umthwalo nge-silencer - ukwehla ngo-1 | ipibekh | 79 | 80 | 79 | 80 | 79 | 80 | 79 | 80 | 79 | ||

|

|

| 3Ti | 5Ti | I-6Ti | 8Ti | I-10Ti | I-15Ti | I-16Ti | 20Ti |

| ||

| Ukukhishwa okuncane 1 | mm | 593 | 674 | 674 | 674 | 813 | 898 | 898 | I-1030 |

| ||

| B | mm | 373 | 454 | 454 | 454 | I-548 | 598 | 598 | I-670 |

| ||

| C | mm | 233 | 233 | 233 | 3058 | 3058 | 382 | 382 | 382 |

| ||

| D | mm | 483 | 483 | 483 | 483 | 575 | I-682 | I-682 | 692 |

| ||

| E1 | mm | 40 | 40 | 40 | 40 | 44 | 53 | 53 | 75 |

| ||

| E2 | mm | 30 | 40 | 40 | 40 | 44 | 53 | 53 | 75 |

| ||

| F enkabeni ye-hook | mm | 154 | 187 | 187 | 197 | 197 | 219 | 219 | 235 |

| ||

| G Ububanzi obuphezulu | mm | 233 | 233 | 233 | 233 | I-306 | 3058 | 3058 | 315 | |||

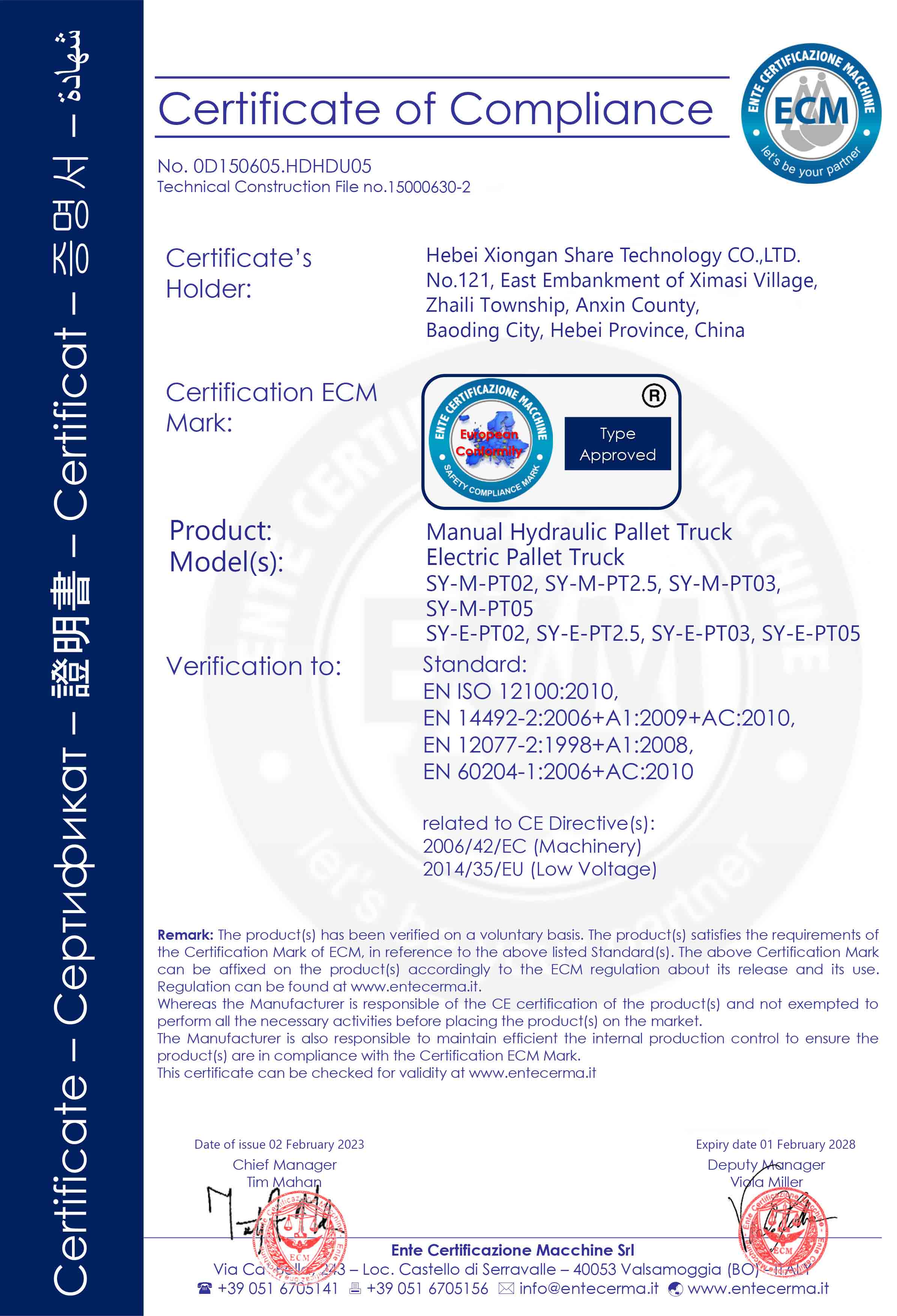

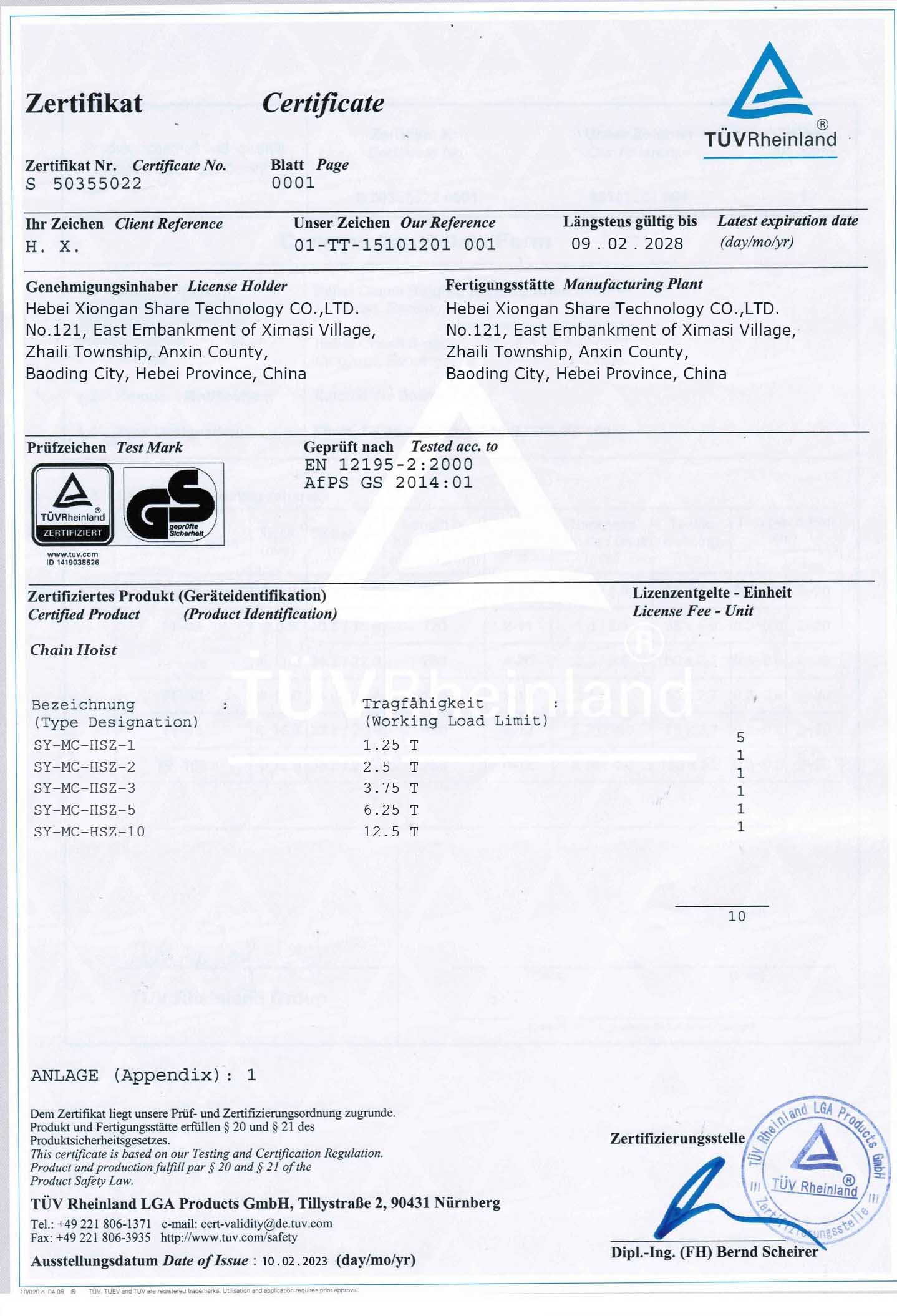

Izitifiketi zethu