Ukugcina apallet jackKubalulekile ekuqinisekiseni ukusebenza okubushelelezi nokusebenzayo ezindaweni zokugcina izimpahla, amafektri, kanye nezinye izilungiselelo zezimboni. Phakathi kwemisebenzi yokulondolozwa okubucayi, ukugcina izinga lamafutha afanele libanda kakhulu. Kulesi siqondisi esiphelele, sizokwehla sijule ngokubaluleka kokulungiswa kwamafutha ama-pallet jacks futhi sinikeze ngezinyathelo ezinemininingwane yokuthi ungawagcwalisa kanjani amafutha ukugcina imishini yakho isesimweni sakho.

Ukubaluleka Kokulondolozwa Komafutha:

1. Ukusebenza okubushelelezi: Uhlelo lwe-hydraulic lwe-pallet jack ukuthembela kumafutha ukuze kusebenze kahle. Amazinga ezanele kawoyela anempilo aqinisekisa ukuphakamisa okubushelelezi nokusebenza ngokuzikhandla nokwehlisa imfoloko, efaka isandla ekukhiqizeni umkhiqizo kanye nokusebenza kahle emisebenzini yokuphatha impahla.

2 Ukulungiswa kwamafutha ejwayelekile kusiza ukuvikela ukulungiswa okubizayo nangesikhathi sokuphumula.

3. Ukuphepha: Ama-pallet jacks agcinwe kahle aphephe ukusebenza. Ukuqinisekisa izinga lamafutha afanele kunciphisa ubungozi bokungasebenzi kahle noma ukwehluleka okungalindelekile okungabeka izingozi zokuphepha kubasebenzisi nabasebenzi abaseduze.

I-4.Longity: Ama-pallet jacks agcinwe kahle anempilo yenkonzo ende. Ngokuhlola njalo nokukhulisa uwoyela, unganweba isikhathi sokuphila kwemishini yakho futhi wandise ukubuyela kwayo ekutshalweni kwemali.

Umhlahlandlela wesinyathelo ngesinyathelo sokugcwalisa amafutha e-pallet jack:

1. Hlanganisa imishini edingekayo:

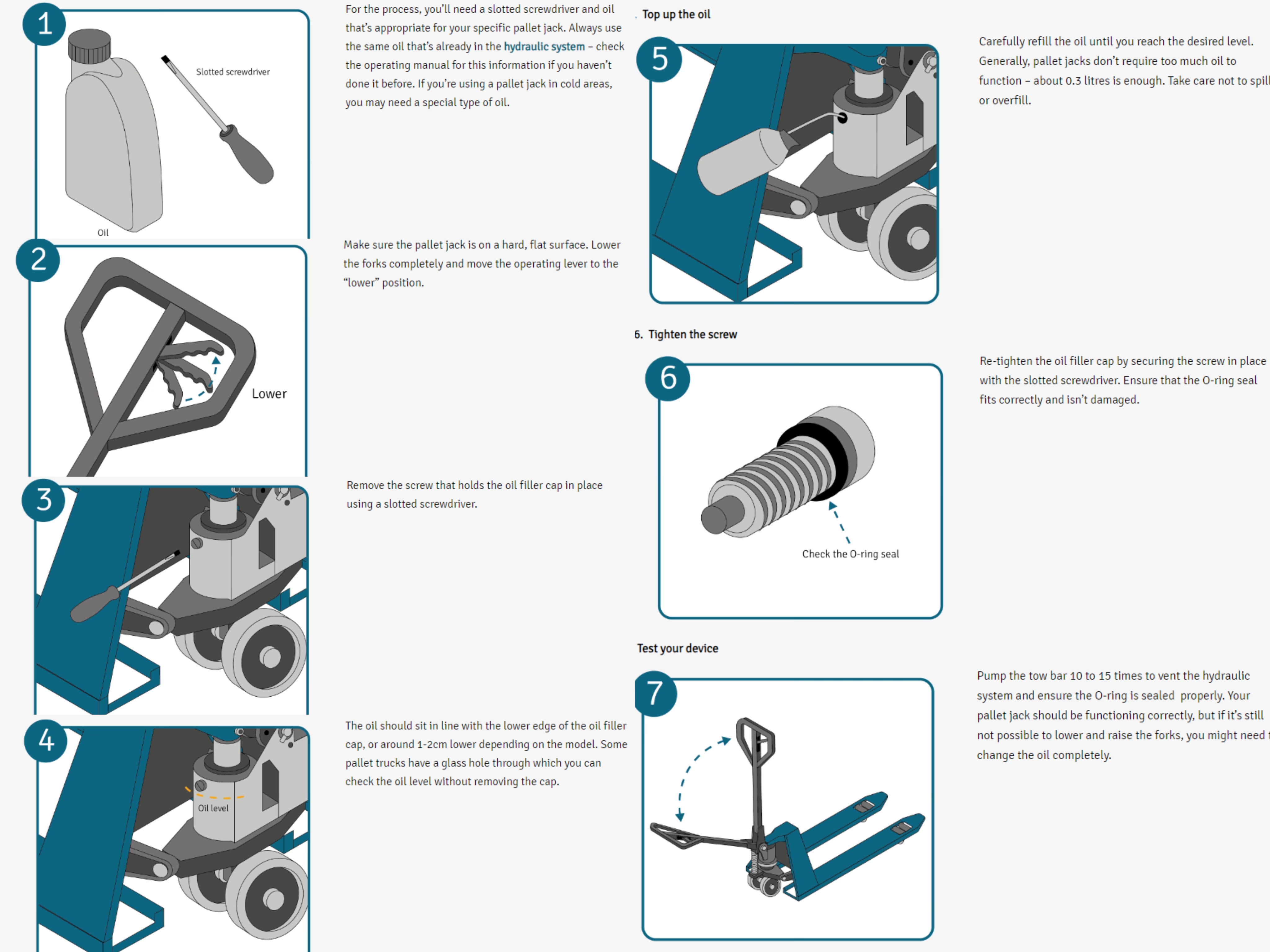

Ngaphambi kokuqala inqubo yokugcwalisa kabusha kawoyela, qiniseka ukuthi unamathuluzi nezinto zokwakha ezidingekayo. Uzodinga i-screwdriver ebekiwe kanye namafutha alungele i-pallet jack yakho. Bheka incwajana yokusebenza ukunquma uhlobo lwamafutha afanele ngemodeli yakho ethile.

2. Lungiselela i-pallet jack:

Beka i-pallet jack endaweni enzima, eyisicaba ukuqinisekisa ukuqina ngesikhathi senqubo yokulungisa. Yehlisa imfoloko ngokuphelele bese usetha i-lever esebenzayo esimweni esithi "esiphansi" ukukhipha noma yimuphi umfutho ohlelweni lwe-hydraulic.

3. Finyelela i-oyili filler cap:

Sebenzisa i-screwdriver efihliwe ukususa isikulufa esibambe i-oyili filler cap endaweni. Phakamisa ngokucophelela i-cap ukufinyelela i-kawoyela reservoir.

4. Bheka izinga lamafutha:

Njengoba kususwe i-oyili ye-filler cap, kuhlola izinga lamafutha endaweni yokugcina amanzi. Amafutha kufanele ahambisane kahle nonqenqema olungaphansi lwe-filler cap noma cishe i-1-2cm ngezansi, kuya nge-Pallet Jack Model. Amanye amaJackle ama-Pallet angaba nefasitela elisobala lokuhlola okulula kwamafutha.

5. Phezulu uwoyela:

Uma izinga lamafutha lingaphansi kwebanga elinconyiwe, uthele ngokucophelela inani elifanele lamafutha ukuze ufinyelele ezingeni olifunayo. Gwema ukugcwalisela i-reservoir, ngoba lokhu kungaholela ekucindezelweni ngokweqile kanye nomonakalo ongaba khona ohlelweni lwe-hydraulic. Ngokuvamile, ukungeza ngawo-0,3 amalitha kawoyela kwanele kumaJacks amaningi wePallet.

6. Vikela i-cap filler cap:

Lapho nje i-oyili sekwenziwe phezulu, iphinde ngibeke i-cap filler cap ku-reservoir futhi uyivikele endaweni ngokuqinisa isikulufa nge-screwdriver ebekiwe. Qinisekisa ukuthi uphawu lwe-O-Ring lubekwa kahle futhi lungafaneleki ukuvikela ukuvuza kawoyela.

7. HlolaPallet jack:

Ukuqinisekisa ukubekwa uphawu okulungile nokusebenza kohlelo lwe-hydraulic, mpompela ibha yethayela izikhathi eziyi-10 kuye kwezingu-15 ukukhipha noma yimuphi umoya obhajwe bese usabalalisa uwoyela ngokulinganayo. Hlola i-pallet jack ngokwehlisa futhi unyuse imfoloko izikhathi eziningi ukuqinisekisa ukusebenza okubushelelezi.

Ngokulandela lezi zinyathelo nokufaka ukulungiswa kwamafutha ajwayelekile kwinqubo yakho yokulungisa ye-pallet jack, ungaqinisekisa ukusebenza kahle, isikhathi eside, kanye nokuphepha kwemishini yakho. Khumbula ukuhlela amasheke ngezikhathi ezithile kanye namafutha aphezulu njengoba kudingeka ukugcina i-Pallet Jack yakho esesimweni seminyaka esizayo.

Ukungeza okuhlangenwe nakho komuntu siqu:

Ngokungeziwe kumhlahlandlela ophelele ku-Pallet Jack Fail Soeal, ngithanda ukuhlanganyela okuhlangenwe nakho komuntu siqu okugqamisa ukubaluleka kokugcinwa ngenkuthalo.

Ngonyaka owedlule, ngenkathi ebheka imisebenzi yokugcina izimpahla, ngahlangabezana nesimo lapho enye yamaJacks ethu e-Pallet aqala khona ukubhekana nobunzima ekuphakamiseni imithwalo esindayo. Ekuqaleni, sasola udaba olwenziwe ngomshini futhi sabiza uchwepheshe ukuze ahlolwe. Kodwa-ke, lapho sihlola ukusondelana, sathola ukuthi izinga lamafutha ohlelweni lwe-hydraulic laliphansi kakhulu.

Ukucabanga ngalesi sigameko, ngabona ukuthi sasikunaka ukubaluleka kokulungiswa kwamafutha ajwayelekile. Naphezu kokuthola uhlelo lwesondlo endaweni, kwakulula ukuphuthelwa yizimpawu ezicashile zokuphatheka kawoyela, ikakhulukazi ngesikhathi esimatasa. Lokhu kwengalo akugcini nje ngokuholelwa isikhathi esingalindele kodwa futhi kwathola nezindleko ezingeziwe zokulungisa ezazingagwenywa ngokulungiswa okufanele.

Lokhu okuhlangenwe nakho kwasebenza njengesifundo esibalulekile eqenjini lethu, kugcizelela indima ebalulekile yemikhuba yokulungisa esebenzayo. Kusukela lapho, sisebenzise amaphrothokholi wesondlo eqinile kawoyela, kufaka phakathi amasheke ajwayelekile we-OIL FAEL FAED ahlelwe. Ngokuhlala i-Vigilant futhi isebenza, sikwazile ukuvimba izehlakalo ezifanayo futhi siqinisekise ukusebenza okungaphazamiseki esikhungweni sethu.

Ngokwabelana nale anecdote yomuntu siqu, ngithemba ukugcizelela ukubaluleka kokulungiswa kwamafutha futhi ngigqugquzele abanye ukubeka phambili lesi sici esibalulekile sokunakekelwa kwe-pallet jack. Ngokukhuthala nangokunaka imininingwane, singanciphisa ubungozi, ukusunduza i-LifeSpan Yokuphila, futhi silondoloze indawo ephephile nesebenza kahle.

Isikhathi Sokuthumela: Mar-27-2024