Ama-pilducts

Sinikezela ngezixazululo ezahlukahlukene zezidingo zakho, noma ngabe udinga izinto ezijwayelekile noma umklamo okhethekile.Uhlobo lwe-PIN esindayo

Incazelo Esikhathi Eside

Izici ezibalulekile zomjondolo zifaka:

1. Ukuqina: Kwenziwe ngezinsimbi ezinamandla aphezulu njengensimbi engagqwali noma ama-alloys ukuqinisekisa ukuqina nokubekezelela izimo ezahlukahlukene zezemvelo.

2. Ukusebenziseka kalula: Umjondolo wenzelwe ukulula, okuvumela abasebenzisi ukuthi bavule kalula noma bayivalele ukuxhumeka okusheshayo nokusebenzayo noma ukunqamula.

I-3. Ukuguquguquka okuhlukahlukene

4

I-5

Isishuqulu

Isicelo

Ezinye izinkombandlela zokusetshenziswa ezibalulekile

Hlola njalo:Ngaphambi kokusetshenziswa ngakunye, hlola ngokuphelele umjondolo nganoma yiziphi izimpawu zokugqoka, ukonakala, noma ukulimala. Nakisisa i-PIN, umzimba, bese ukhothama imifantu, ukugoba, noma ukugqwala.

Khetha uhlobo olufanele:Imijondolo iza ngezinhlobo ezahlukahlukene, ngamunye owenzelwe izinhlelo ezithile. Qinisekisa ukuthi ukhetha uhlobo olufanele lomjondolo nosayizi osuselwa kwizidingo zomthwalo nemibandela yokusebenzisa.

Bheka imikhawulo yokulayisha:Njalo shackle inomkhawulo osetshenzisiwe wokusebenza (WLL). Ungalokothi udlule lo mkhawulo, bese ubheka izici ezinjenge-angle yomthwalo, njengoba kuthinta umthamo we-shackle.

Ukufakwa kwe-PIN efanele:Qinisekisa ukuthi i-PIN ifakwe kahle futhi ivikelwe. Uma i-PIN uhlelo lwe-bolt, sebenzisa ithuluzi elifanele ukuze liqinise kwi-torque enconyiwe.

Gwema Ukulayisha Eceleni:Ama-shackles aklanyelwe ukuphatha imithwalo ngokuhambisana ne-axis ye-shackle. Gwema ukulayisha uhlangothi, ngoba lunganciphisa kakhulu amandla kaCackle futhi uholele ekwehlulekeni.

Sebenzisa igiya lokuvikela:Lapho usebenzisa imijondolo ezimweni lapho zingadalulwa khona izinto ezi-abrasive noma imiphetho ebukhali, cabanga ngokusebenzisa amagiya okuvikela afana namaphaphu enjoloba ukuvimbela ukulimala.

| Into No. | Isisindo / lbs | Wll / t | Bf / t |

| Sy-3/16 | 6 | 0.33 | 1.32 |

| Sy-1/4 | 0.1 | 0.5 | 12 |

| SY-5/16 | 0.19 | 0.75 | 3 |

| Sy-3/8 | 0.31 | 1 | 4 |

| Sy-7/16 | 0.38 | 15 | 6 |

| Sy-1/2 | 0.73 | 2 | 8 |

| Sy-5/8 | 1.37 | 325 | 13 |

| Sy-3/4 | I-2.36 | 4.75 | 19 |

| Sy-7/8 | 3.62 | 6.5 | 26 |

| Sy-1 | I-5.03 | 8.5 | 34 |

| Sy-1-1 / 8 | 741 | 9.5 | 38 |

| Sy-1-114 | 9.5 | 12 | 48 |

| Sy-1-38 | 13.53 | 13.5 | 54 |

| Sy-1-1 / 2 | 17.2 | 17 | 68 |

| Sy-1-3 / 4 | 27.78 | 25 | 100 |

| Sy-2 | 45 | 35 | 140 |

| Sy-2-1 / 2 | 85.75 | 55 | Ama-220 |

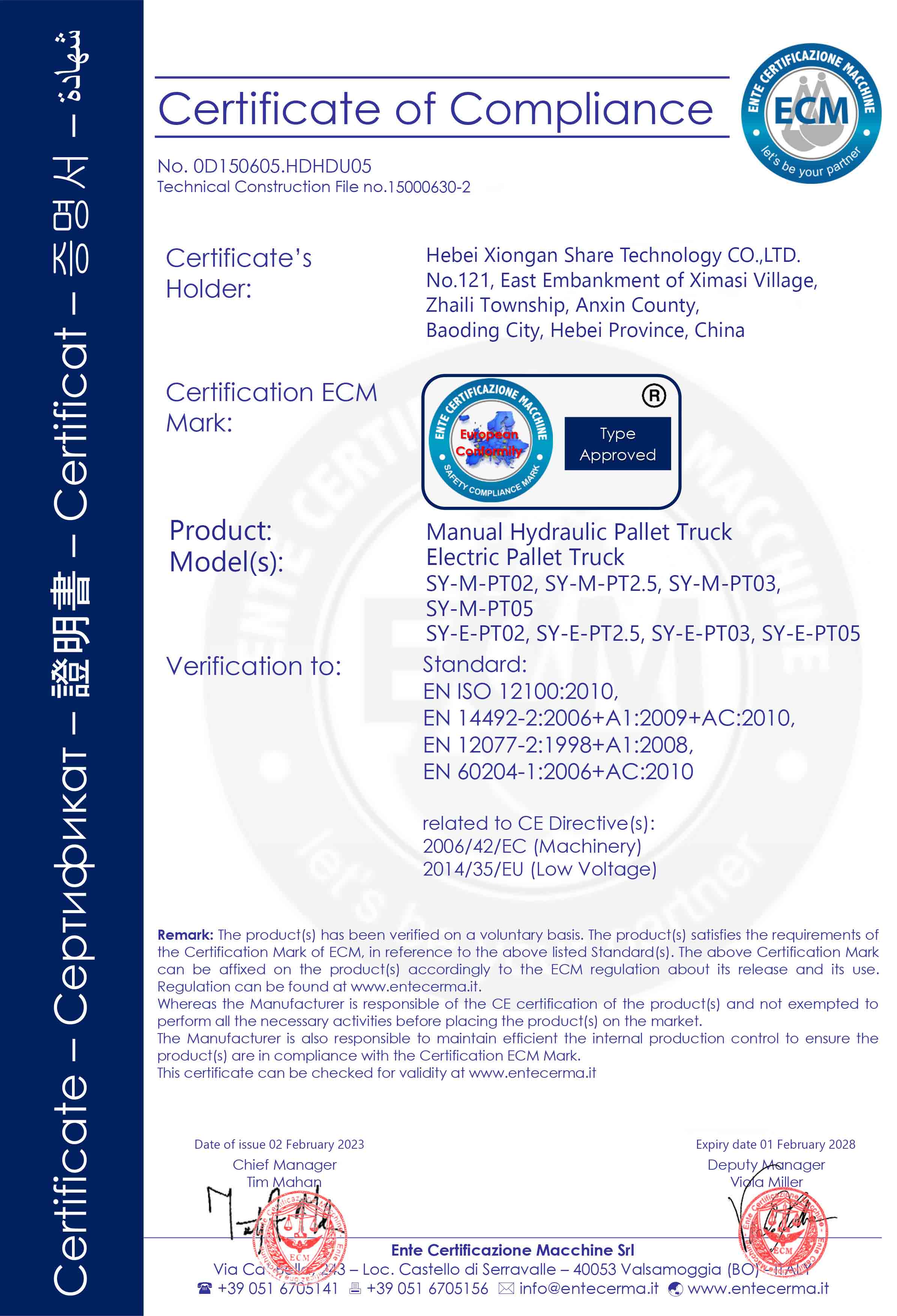

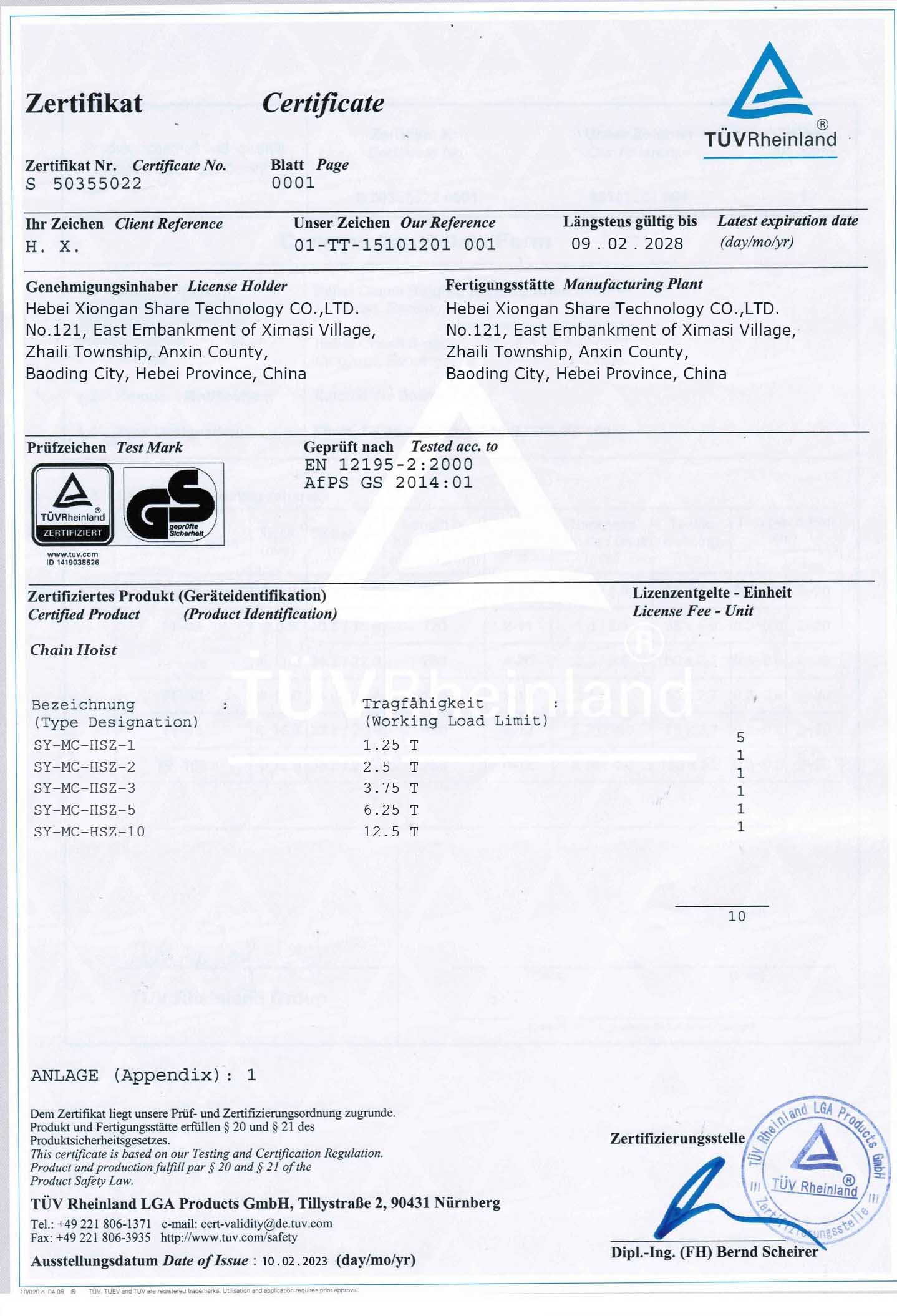

Izitifiketi zethu